Cases

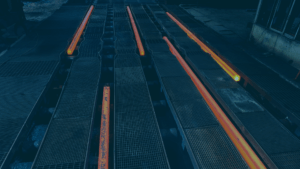

AUTOMATION OF TUBE FINISHING LINE

SUCCESS STORIES– INDUSTRIAL AUTOMATION THE PROBLEM Our client, an international company specializing in the manufacturing of seamless pipes primarily for the oil market, requires an

SUCCESS STORIES– INDUSTRIAL AUTOMATION THE PROBLEM Our client, an international company specializing in the manufacturing of seamless pipes primarily for the oil market, requires an

SUCCESS STORIES – INDUSTRIAL ANALYTICS & BIG DATA THE PROBLEM Organizations face new challenges every day due to the need to be competitive in their

SUCCESS STORIES – IT SOLUTIONS THE PROBLEM Our client, a company specializing in the manufacturing and sale of a wide range of custom-made curtains and

SUCCESS STORIES – IT SOLUTIONS THE PROBLEM Our client, a significant seamless tube manufacturing steel company, presented us with their issue of inefficiencies in their