SUCCESS STORIES – IT SOLUTIONS

Cases

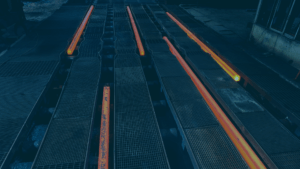

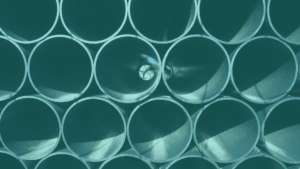

AUTOMATION OF TUBE FINISHING LINE

SUCCESS STORIES– INDUSTRIAL AUTOMATION THE PROBLEM Our client, an international company specializing in the manufacturing of seamless pipes primarily for the oil market, requires an