TAMESIS

The implementation of MES (Manufacturing Execution System) systems in their processes denotes a level of maturity of those manufacturing companies that have come to consider the automation of data capture as the cornerstone of any continuous improvement initiative.

The IIot (Industrial Internet of Things) and MES systems allow us to know the part of the iceberg that remains hidden, in order to complete the analysis not only with the available information, but with all the existing information.

Unlock the potential of the data stored in your hidden factory

Benefits

The benefits of our TAMESIS platform are grouped into three categories:

Productivity

Refers to an improvement, either greater production with the same resources, or the same production with fewer resources.

- Reduction of Work in Progress (WIP)

- Cycle time reduction

- Cost reduction

Agility

Time and cost reduction when introducing new products or modifying processes.

- Definition and implementation of business rules

- System execution and business processes

- Rapid staff training through intuitive interfaces

Quality

Improved production performance; direct impact on customer satisfaction.

- Increased product yield

- Improved delivery times

- Reduction of product returns

Features

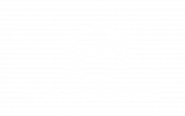

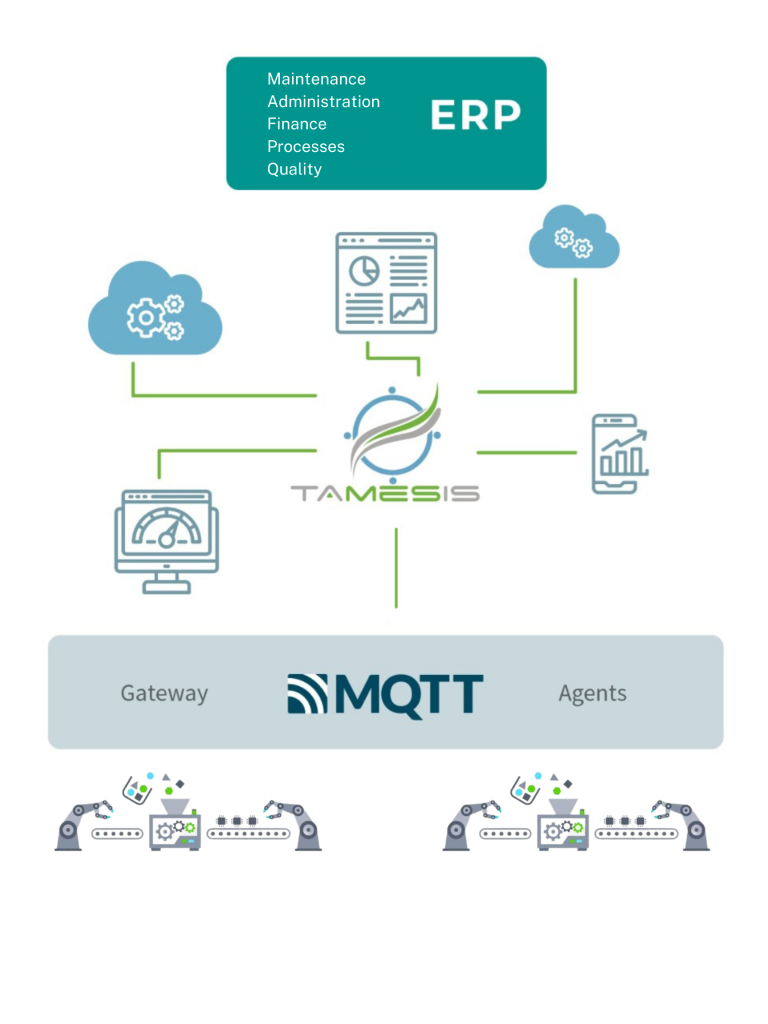

TAMESIS is our iMES system (Intelligence Manufacturing Execution System), it is a bridge between floor control and your ERP; developed under three fundamental principles of Industria 4.0, interconnection, decentralized decisions and online information and dashboarding, which will allow you to increase the Efficiency of your Production Plants (#OEE).

Multi-device visualization

Unlimited users and lines

Manufacturing Programming

Control panels

Process Modeling

Areas of application

Production

Maintenance

Logistics

Quality

Modules

- Industrial Analytics

- Advanced Efficiency with Sensors (IIoT)

- Quality [States & Routes].

- WorkForce Manager

- Manufacturing Intelligence

- Mass Balance/OEE/Traceability

Integration

Integral Process

Recognitions